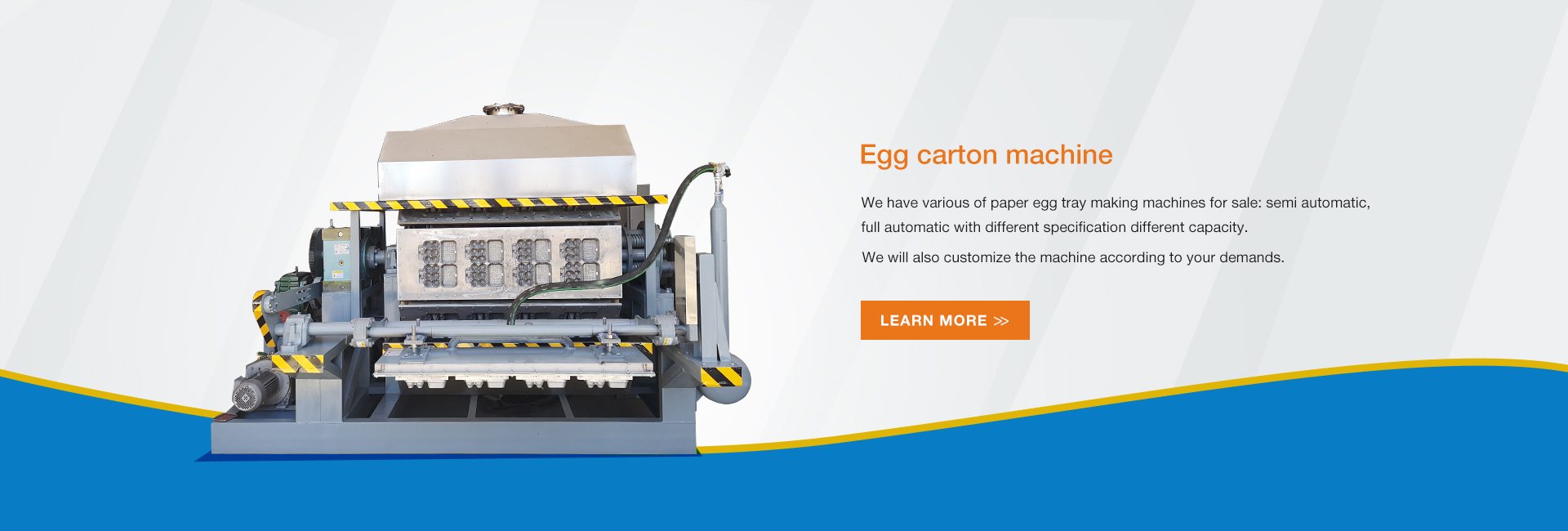

Paper Tray Production Line Forming System

Forming process of paper tray forming machine

The forming system is the most important link in the entire production process.

Paper tray forming machine is a device for producing paper tray. With the wide application of paper trays, many paper tray manufacturers have emerged at home and abroad. The selection of paper tray forming machines needs to be based on the forming process adopted by the paper tray manufacturers.

1.Paper tray forming machine—vacuum suction forming machine, this forming method is a process method that is widely used in paper tray products. According to the different mechanisms of pinhole suction molding, it can be divided into three ways: flip type, drum type, and reciprocating lift type.

2.The paper tray forming machine can use the grouting method, and the suction forming method calculates the required amount of slurry (material) according to different pulp packaging products, and then determines the amount of slurry and injects it into the molding cavity for further adsorption forming.

Workflow Introduction

1. The forming machine adsorbs the pulp pumped into the hopper of the forming machine to the mould of the forming machine, absorbs the pulp onto the mould of the forming machine through the suction of the vacuum system, sucks the excess water into the gas-water separation tank, the water pump draws the water into the water pool.

2. The mould of the forming machine absorbs the pulp and then takes out the finished product by the manipulator of the forming machine.

Screw type variable frequency air compressor

gas tank

High pressure mold cleaning machine

water pump

Packing machine

Automatic stacking counting and receiving machine

Heat shrink mold automatic packaging machine

Vacuum pump

Negative pressure tank

Water pump