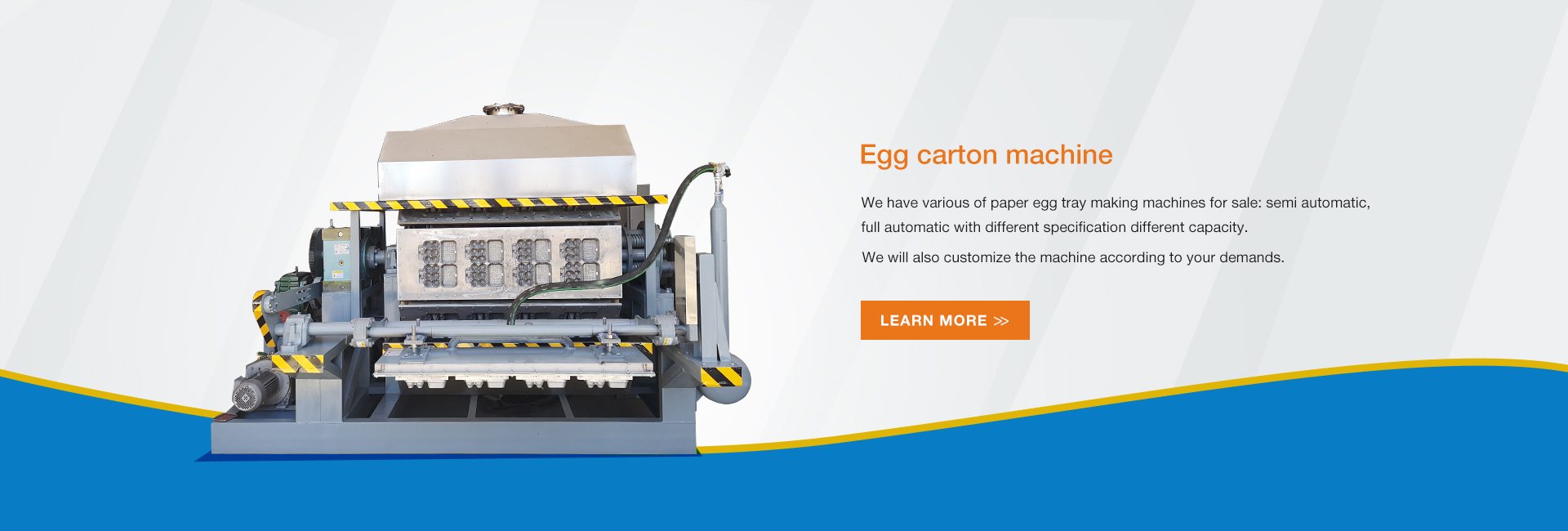

Four sides (2000-5500 pcs/hr)

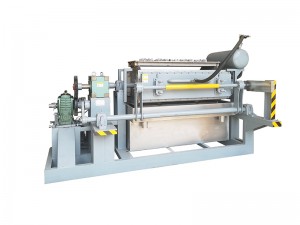

Equipment overview

This equipment is a four-side rotary forming machine, which is composed of forming templates, transfer templates, worm reducers, motors, intelligent control appliances, high-precision dividers, solenoid valves and other components. The drive motor drives the worm reducer to drive the divider to make the equipment move intermittently.

YZ-4X2000(3-4) egg tray machine is mainly used for the production of pulp molding products such as egg trays, coffee cup trays, fruit trays and medical trays, etc.

The drying method is generally natural drying.

YZ-4X3000 (4-4) egg tray machine is mainly used to produce pulp molded products such as egg trays, coffee cup trays, fruit trays and medical trays. The drying method is generally natural drying or dryer.

YZ-4X4000(4-5) full-automatic egg tray production line can produce automatically. This egg tray machine can produce various specifications of egg trays, paper coffee cup holders, fruit trays, medical pulp trays and other pulp molded products.

YZ-4X5000 (4-6) full-automatic pulp egg tray machine can be produced automatically. This egg tray equipment can produce various specifications of egg trays, paper coffee cup holders, fruit trays, medical pulp trays and other pulp molded products.

Parameters

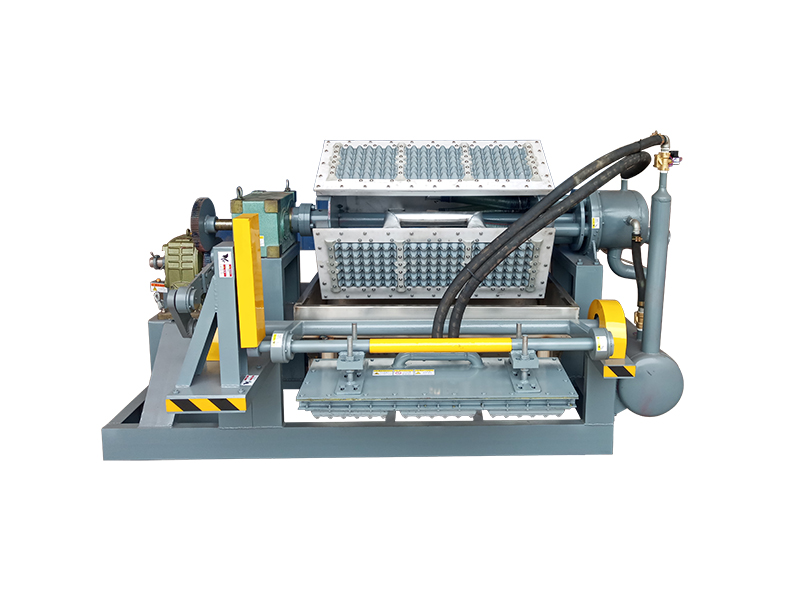

YZ-4X2000(3-4)

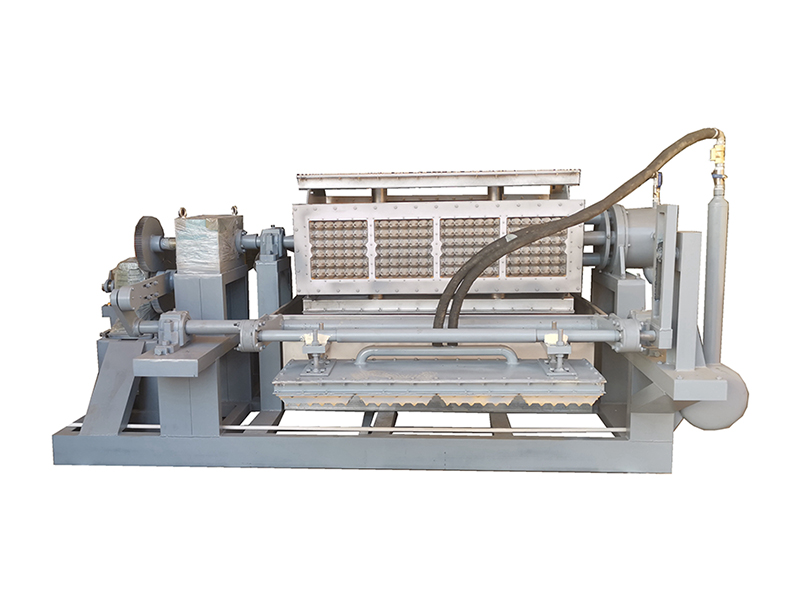

YZ-4X3000(4-4)

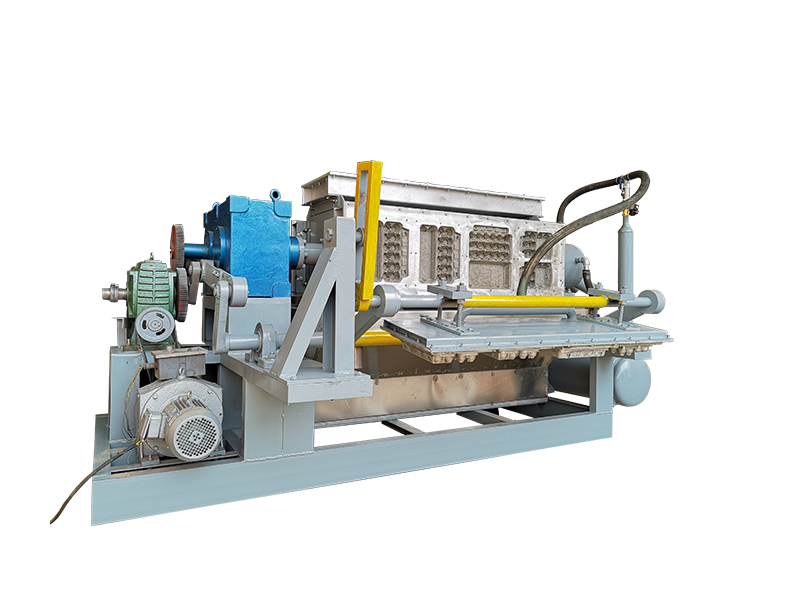

YZ-4X4000(4-5)

| Model | YZ-4X2000(3-4) | YZ-4X3000(4-4) | YZ-4X4000(4-5) | YZ-4X5000(4-6) | ||

| Capacity/hour | 2000-2500pcs | 2500-3500pcs | 3500-4500pcs | 4500-5500pcs | ||

| Template size | 1250MMX470MM | 1470MMX470MM | 1800MMX470MM | 2100MMX470MM | ||

| Number of molds | 12+3 boxes | 16+4boxes | 20+5boxes | 24+6boxes | ||

| Operating mode of forming machine |

Rotary drum suction molding |

|||||

| Molding cycle |

10-15 times/minute |

|||||

| Power | 57kw | 60kw | 60kw | 65kw | ||

| labour | 3 person/shift | 4 person/shift | 5 person/shift | 5 person/shift | ||

| Paper | 170kg/hour | 212kg/hour | 200kg/hour | 3500kg/hour | ||

| Water | 510kg/hour | 636kg/hour | 600kg/hour | 1050kg/hour | ||

| Product height that can be produced |

70mm |

|||||

| Drying method | Natural drying |

Naturally air-dry the product through sunlight and natural breeze |

||||

| dryer |

A:Traditional brick dryer B:Metal multi-layer dryer Heat energy can be used: coal, natural gas (LNG), diesel, liquefied petroleum gas( LPG), heat transfer oil, steam and other heat energy |

|||||

| 1. The capacity of the equipment is calculated based on the production of 30 egg trays with a size of 300*300mm and a dry tray weight of 70g.2. Various specifications of equipment can be customized according to customer requirements. | ||||||